Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

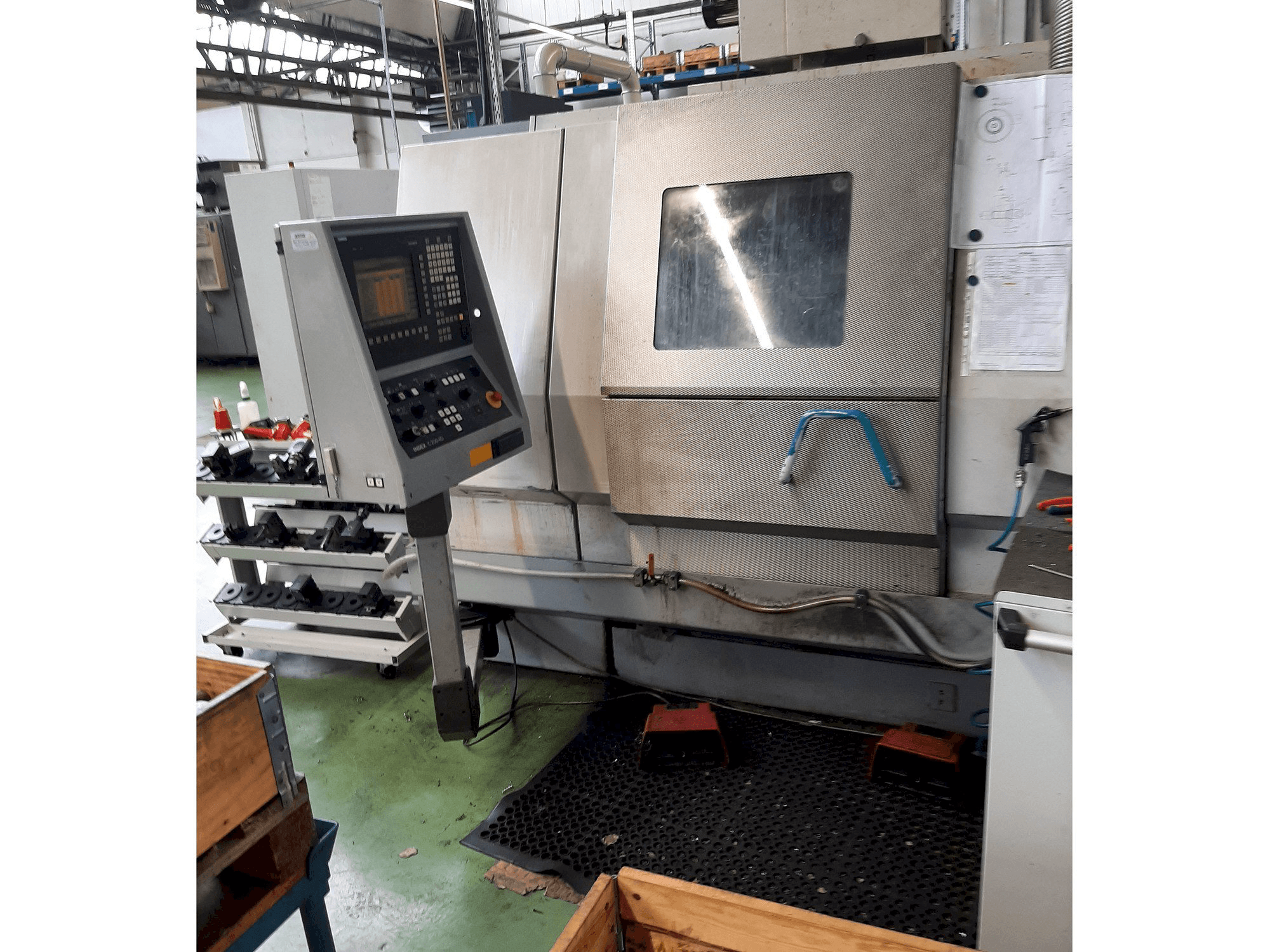

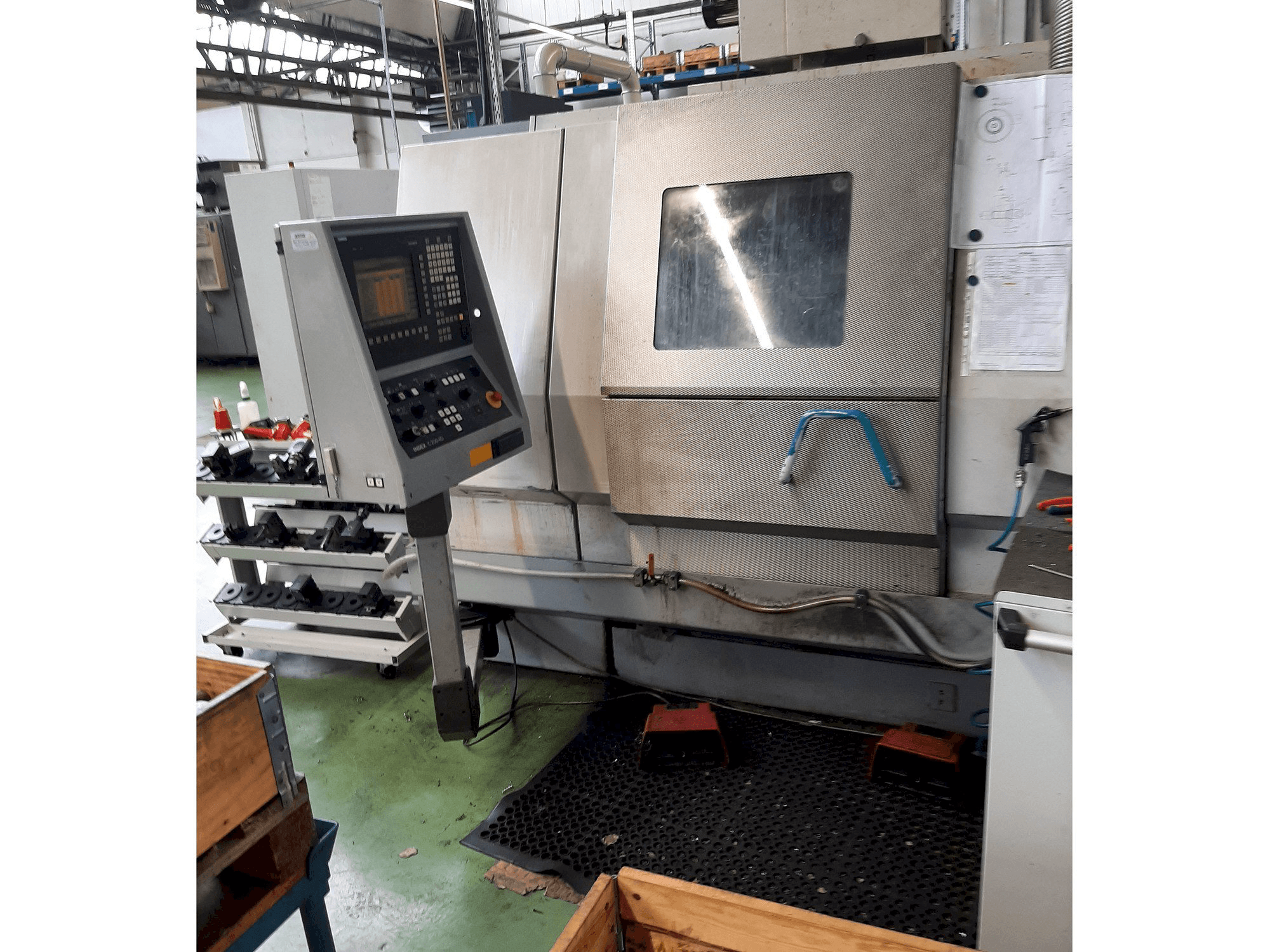

Index - G200DE-TUR-IND-2002-00004

Sold

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

Click to chat on WhatsApp

- GINDUMAC

- Products

- Machine Tools

- Index G200

This Index G200 Lathe was manufactured in 2002 in Germany. It is equipped with a SIEMENS SINUMERIK control unit. This machine stands out for its spindle speed up to 5000 rpm and a material passage 60 mm.

Overview

- brand: Index

- year: 2002

- MODEL: G200

- application type: Turning

- Location: Germany

- machine type: Horizontal Turning Machine

- control unit brand: SIEMENS

Technical Information - Index G200

Control Unit

- Control Brand: SIEMENS

- Control Model: SINUMERIK

Dimensions

- Machine Weight: 4800 kg

Technical Specification

- Spindle Power: 100 kW

- Spindle Speed: 5000 RPM

- Through-spindle Coolant: Yes

Additional Information

Additional equipment

- Bar feeder is not included in the scope of delivery

- The scope of delivery includes the machine tool together with chip conveyor, high-pressure coolant system, filter system (fleece) and parts conveyor.

- The mounted tool holders remain in place

Machine Benefits

Qualitative Machine Benefits

- Counter spindle working stroke 445 mm; rapid traverse speed 22. 5 m/min

- Slide driven in z-direction via ac motor and ball screw d=32 mm, axis drive secured by overload clutch secured.

- In working position the slide is by the ac motor against the stop

- Measuring system in z-axis glass scale

- Power at the counter spindle: power at 100/40 % ed 13/22 kw; torque 61/105 nm

- Cross slide 1 - x/z, with internal coolant supply and shut-off valve

- Shut-off valve, revolving via ac motor, ball screws d = 32 mm,

- Axis drives secured by overload overload clutches, weight compensation in x-axis

- Measuring system x-axis glass scale z-axis rod encoder

- Turret head with 14 stations on cross- slide 1; tool mounting holes for cylinder shank din 69880 - 25x48 mm, positioned by face gear, hydraulically locked

Technical Machine Benefits

- Axis x/z working stroke 120 / 400 mm; working stroke 105 / 400 mm

- Cabinet mass 440 kg

- Spindle head admission ad 140 mm, id 85 mm

- Material passage max. Mm 60; front bearing diameter 100 mm; adjustable three-phase drive

- Hollow shaft motor: torque nm 95/140

- Main spindle alignment and switching device d42/d60/d65, graduation 2. 5 degrees via indexing disc

- Hollow clamping cylinder d60/20 for collet and clamping on the main spindle, hydraulically operated, including end of clamping stroke monitoring

- Tensile- compressive force ( 57 cm2 ) max 45 kn

- 1-clamping-pressure device for clamping cylind- on the main spindle, adjustment range 10 to 80 bar, set to the adjusted to the maximum permissible clamping operating force of the clamping medium or pressure tube

- Counter spindle d60; spindle head admission ad 140 mm, id 85 mm

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Your account manager:

Borja Garcia

Borja Garcia is one of our used machinery trading experts and will be your direct contact for any further questions on the machine. Feel free to contact him/her.

Payment Terms

Payment in advance

Asset Financing