Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

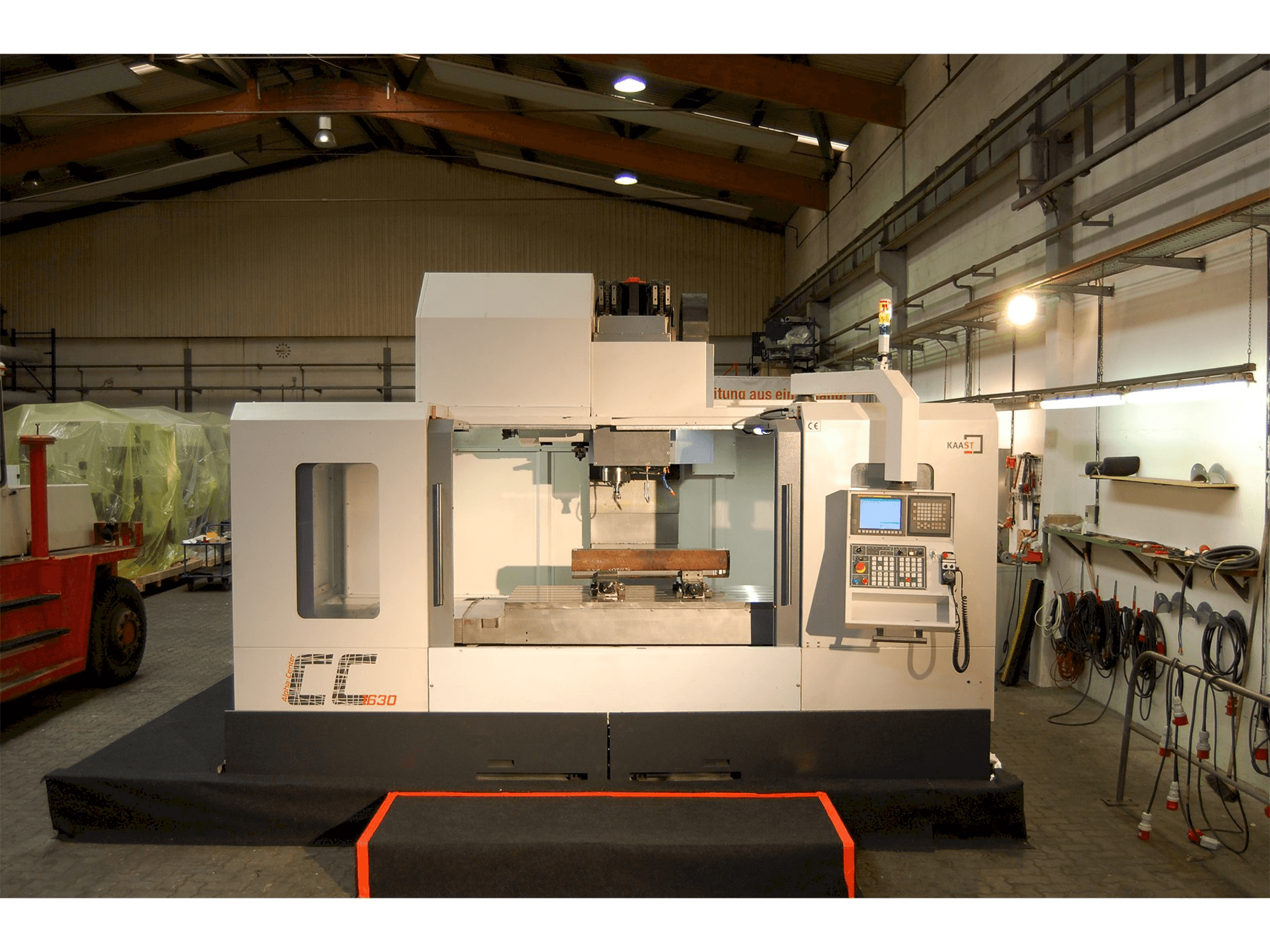

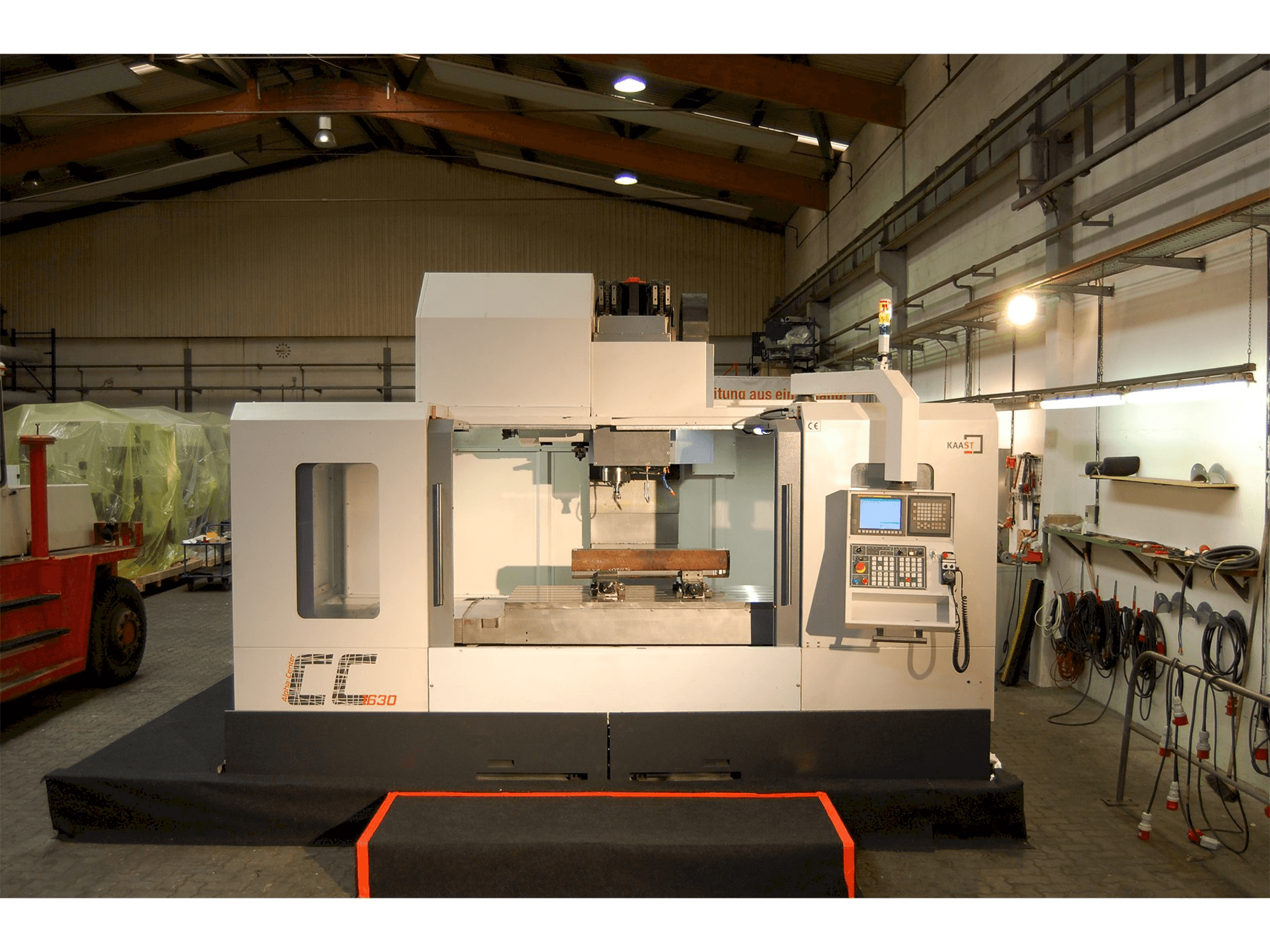

Kaast - CC1630DE-MIL-KAA-2015-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- Kaast CC1630 Vertical Machining Center

This Kaast CC1630 Vertical Machining Center from 2015 was made in Germany and has 4500 production hours, of which 1000 are spindle hours. This 3 axis with hydraulic clamping to build up machine is operated through a Fanuc Oi MD control unit. This machine counts with a spindle speed up to 9000 rpm and spindle motor power of 18.5 kW.

Overview

- brand: Kaast

- year: 2015

- MODEL: CC1630

- production hours: 4500

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

- control unit brand: FANUC

Technical Information - Kaast CC1630

Control Unit

- Control Brand: FANUC

- Control Model: Oi MD

Dimensions

- Machine Depth: 3580 mm

- Machine Weight: 12600 kg

- Table Length: 1750 mm

- Table Load: 2300 kg

- Table Width: 800 mm

Movement

- Number of Axes: 3

- X-axis Travel: 1630 mm

- Y-axis Travel: 850 mm

- Z-axis Travel: 815 mm

Technical Specification

- Max. Tool Weight: 7 kg

- Spindle Power: 18.5 kW

- Spindle Speed: 9000 RPM

- Taper Size: ISO 40

Additional Information

Additional equipment

- Tool cone DIN 69871 ISO 40

- Tool magazine for 28 tools/ arm changer

- Full protection cabin with "Top Close

- Control cabinet temperature control

- Halogen work area light

- Coolant outlet around the spindle

- Portable electr. handwheel

- Hinged belt chip conveyor

- Oil separator, Tempered main motor flange plate

- 4+5 axis included

Machine Benefits

Qualitative Machine Benefits

- Z-axis as block guide

- Ktr couplings

- Thk linear guides x and y, z flat guides

- Set-up elements

- Operating tool

- Operating instructions

Technical Machine Benefits

- Distance spindle-table 100-915 mm

- Distance spindle center-z-axis cover 860 mm

- Positioning accuracy ± 0. 005 mm

- Repeat accuracy ± 0. 003 mm

- Max. Tool tool without adjacent tool 130 mm

- Tool change time 2. 2 sec

- Air pressure 7 kg/cm²

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing