Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

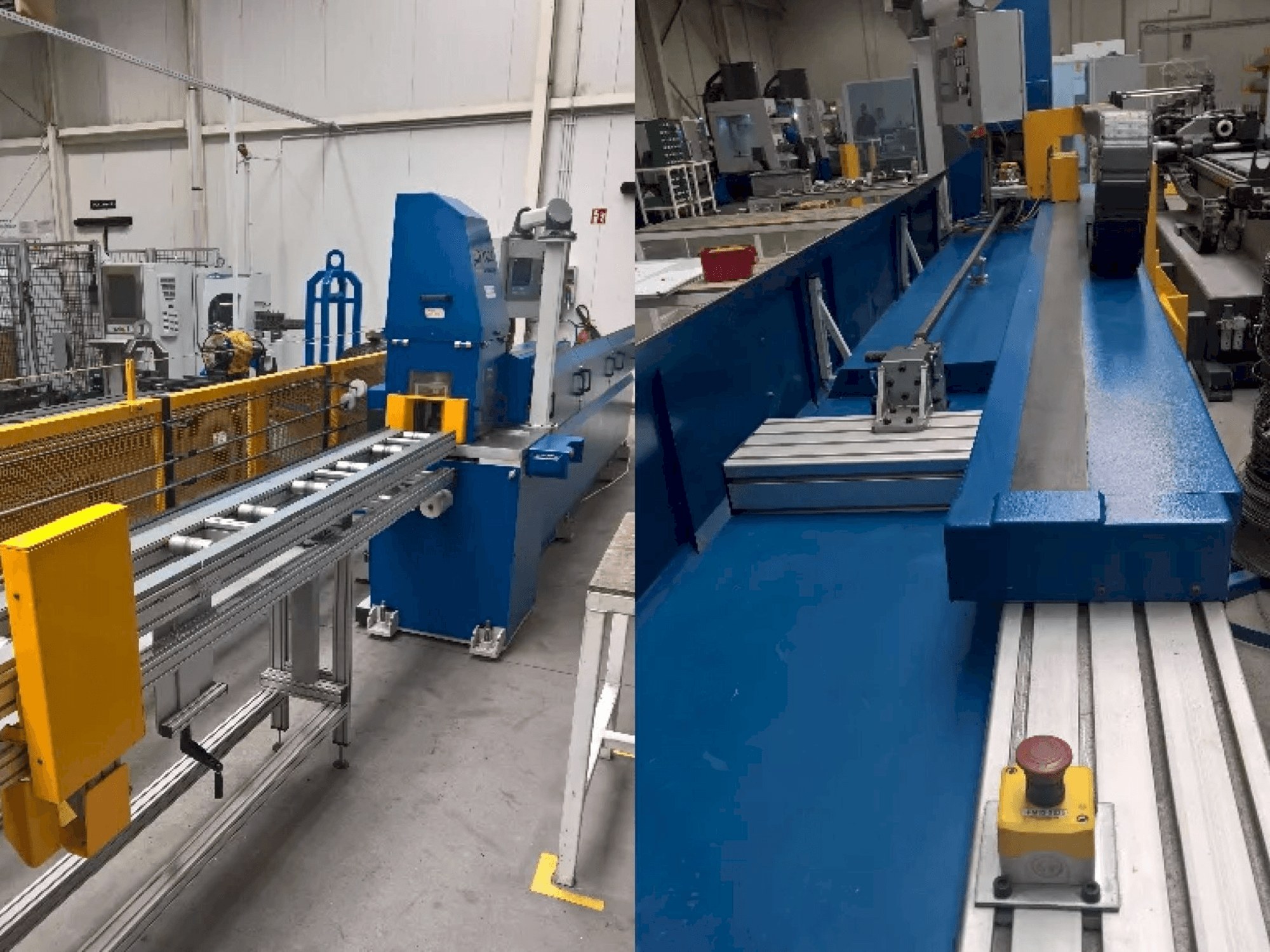

PARS - HPM SIRIUS PLUS - 3000/6 LH-1PL-PUN-PAR-2014-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Sheet Metal Machinery

- PARS HPM SIRIUS PLUS - 3000/6 LH-1 Punching Machine

This PARS HPM SIRIUS PLUS - 3000/6 LH-1 Punching Machine was manufactured in Czech Republic in the year 2014. This machine works with a punching force of 151 kN and a maximum sheet thickness of 4 mm. Hydraulic machine with automatic profile feed by means of an electric linear drive with a magnetic coupling. The presented machine is the highest series of machines designed to work under high time load (3 shift work). The presented device is a new one, improved in 2012. machine model (the latest models of Siemens controllers). The machine is controlled fully automatically thanks to the CNC digital control. Depending on the equipment, the profiles can be round, rectangular, square, triangular, oval, type D or open. Thanks to the special hydraulic and electronic control solution (option), the press can work in both directions. This solution allows the use of special equipment to punch holes and pull out flanges in steel profiles.

Overview

- brand: PARS

- year: 2014

- MODEL: HPM SIRIUS PLUS - 3000/6 LH-1

- application type: Punching

- Location: Poland

- machine type: CNC Punching Machine

- control unit brand: SIEMENS

Technical Information - PARS HPM SIRIUS PLUS - 3000/6 LH-1

Control Unit

- Control Brand: SIEMENS

Dimensions

- Machine Depth: 2100 mm

- Machine Height: 1200 mm

- Machine Weight: 2100 kg

Movement

- X-axis Travel: 6000 mm

Technical Specification

- Punching Force: 151 Kn

Additional Information

Machine Benefits

Qualitative Machine Benefits

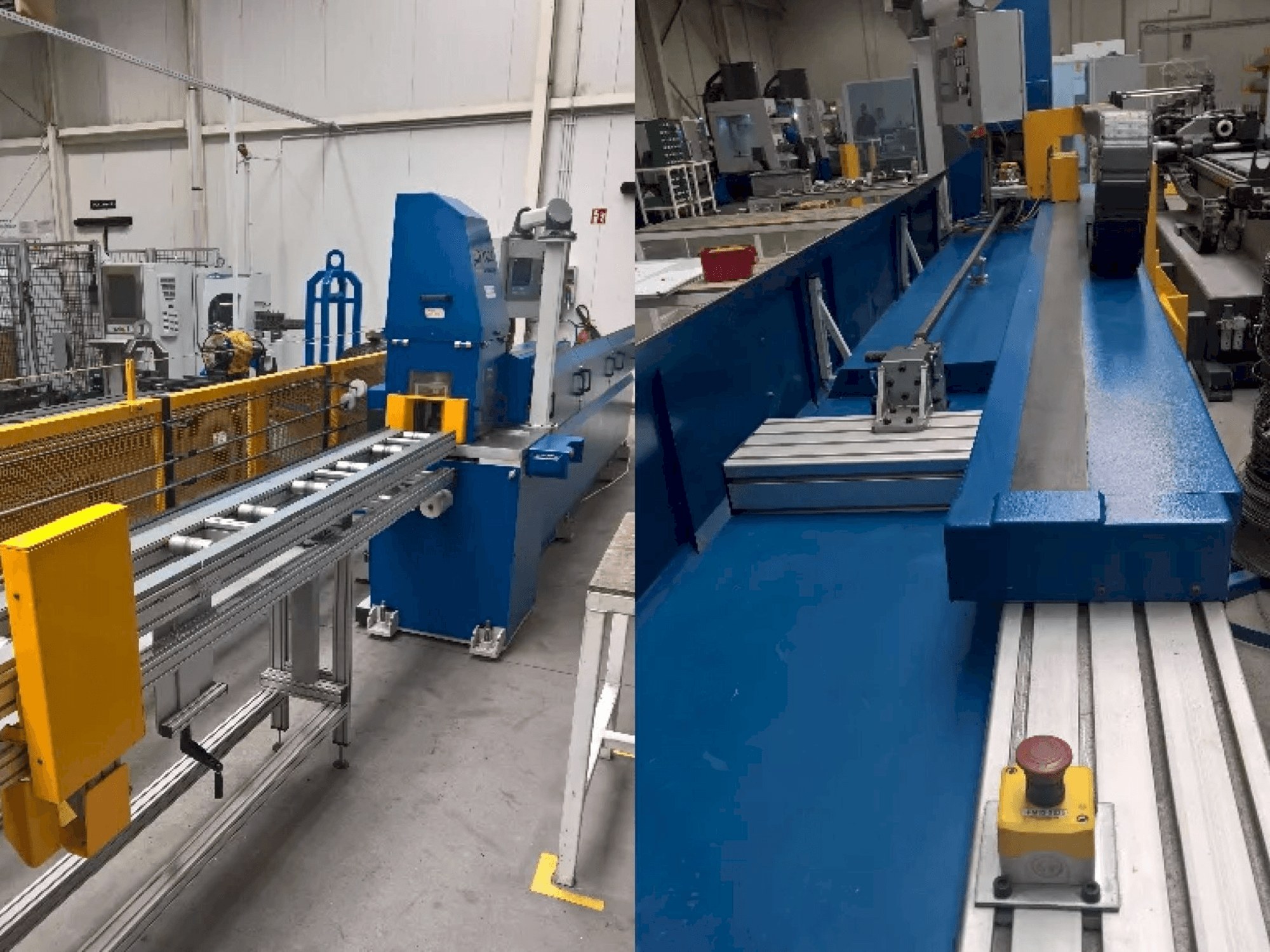

- Material feed. Automatic, linear electric motor with separation from the external environment protection against punching profiles with a length outside the specified tolerance

- Measurement of the laser profile length

- Quick punching tool change system

- Turntable for pipes 0-180º

- Automatic lubrication, micron oil mist spray

- Program control of the range of movement of the hydraulic cylinder of the press

- Memory of punching programs

- Tool change time / 1 head approx. 15-20 min.

Technical Machine Benefits

- Possibility of punching in 4 sides of the profile and programming in one recipe yes

- Punching speed 0. 9-1. 2 s / hole

- Positioning accuracy up to ± 0. 1 mm between holes

- Profile / tube size 80xl00mm, d = 80mm

- Feeding / receiving table with hydraulic height adjustment

- Profile holder automatic, hydraulic

- Pneumatic blow-out of waste

- Remote machine diagnostics via the internet (vpn)

- Uploading punching programs via the company's internal network or usb memory stick

- The ability to edit programs on a pc

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing