Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

AXA - VSC 1-5000M/EDE-MIL-AXA-1998-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- AXA VSC 1-5000M/E

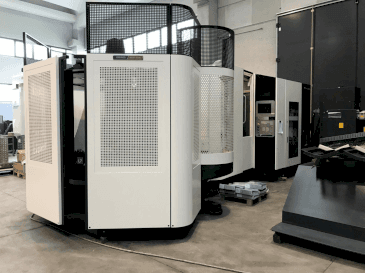

This AXA VSC 1-5000M/E Vertical Machining Center was manufactured in 1998 and overhauled in 2020. It is equipped with a SIEMENS 810 M/GA3 control unit. This 3 axis machine has a spindle speed range 40 - 6000 rpm and a table dimension of 5470 mm x 500 mm. It got a renewal of the emulsion hoses for external cooling and a replacement of the workspace discs and the rubber surrounds between other benefits in its last inspection.

Overview

- brand: AXA

- year: 1998

- MODEL: VSC 1-5000M/E

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

- control unit brand: SIEMENS

Technical Information - AXA VSC 1-5000M/E

Control Unit

- Model: 810 M/GA3

- Brand: SIEMENS

Main drive

- Spindle speed range: 40 - 6000 1/MIN

- Tool taper: SK 40

- Number of axis: 3

Movement

- X-AXIS Movement: 5000 mm

- Y-AXIS Movement: 420 mm

- Z-AXIS Movement: 480 mm

Table

- Outer length: 5470 mm

- Outer width: 500 mm

- Min distance between vertical spindle and table: 170 mm

- Max distance between vertical spindle and table: 650 mm

Tools

- Number of stations: 30

- Type of tool holder: SK 40 DIN69871A / 69872A

Media

- Chip conveyor: Yes

Additional Information

Machine Benefits

Qualitative Machine Benefits

- Cleaning of the machine

- Partial painting of the machine parts

- Renewal of the emulsion hoses for external cooling

- Replacement of the workspace discs and the rubber surrounds

- Surface grinding of the machine tables and readjustment according to the alignment groove

- General overhaul of the slide linings of the cross slide of the x-axis

- New bearing of the main spindle in the axa factory

- Replacement of other defective mechanical parts with original or identical parts

- Checking of the electrical cables for damage and cable breakage and

- New measuring system cables in the x-axis and to the main spindle

Technical Machine Benefits

- New bearing of the main spindle

- Pendulum stroke: 2 x 2300 mm

- In pendulum operation with pendulum stroke in the x-axis, protection is provided by a safety circuit for side detection

- Siemens three-phase motor with spindle blow-out device during tool change

- Chain magazine moving in the x-axis

- Measuring system in x/y/z: direct linear; heidenhain glass scales in x, y, z axes protected in aluminium housing

- X / y basic slide, z column and slide as well as the are made of high-quality machine cast iron

- Hinged belt chip conveyor - discharge right - 300mm feed width, discharge height approx. 1250 mm

- Checking of the emergency stop and safety door safety functions (if necessary, the delivery state is (if necessary, the delivery condition is restored)

- Replacement of defective switches

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to AXA VSC 1-5000M/E

GX 600

Bridgeport - Vertical Machining Centre

TC 32B

Brother - Vertical Machining Centre

HS500i

HYUNDAI KIA - Horizontal Machining Centre

F5

Makino - Vertical Machining Centre

MTV 655/60N

Mazak - Vertical Machining Centre

DECKEL MAHO DMC 60H Linear

DMG - Horizontal Machining Centre

NHP 5000

DN SOLUTIONS - Horizontal Machining Centre

UMC-500SS

HAAS - Universal Machining Centre

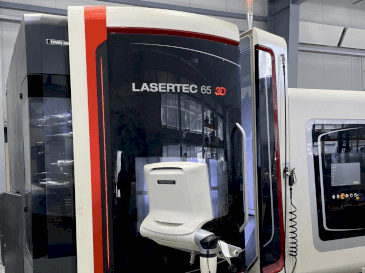

LASERTEC 65 3D Hybrid

DMG MORI - Universal Machining Centre

TM 2

HAAS - Vertical Machining Centre

Robodrill D21MiA5

FANUC - Vertical Machining Centre

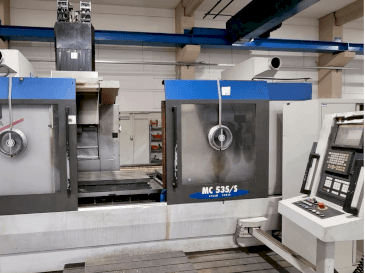

MC 535

STAMA - Vertical Machining Centre