Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

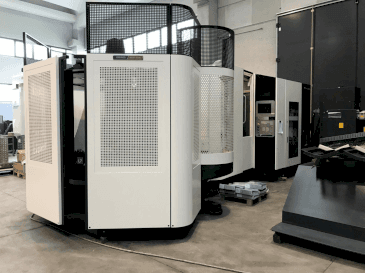

DECKEL MAHO - DMU 80PDE-MIL-DEC-1999-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- DECKEL MAHO DMU 80P Universal Machining Center

This DECKEL MAHO DMU 80P Universal Machining Center was built in the year 1999 and has been working for 56145 hours, from which 27389 are spindle hours. This machine is in a very good condition and can be tested under power. Its table, as well as the tool clamps, were overhauled and got a Heidenhain LE426PB swap computer with a fast SSD hard disk. The Siemens Simodrive LT-Module Interface 108A Type: 6SN1123-1AA00-0LA1 has been exchanged. Also, the spindle encoder has been exchanged. The zero position must be adjusted once a day. The side window has a crack but this does not affect functionality. Many tool holders are converted to IK. Aluminium cover strips has been renewed on the side. Inside and outside include a new spindle cover, and new inscriptions received. New switch on button green. The control panel has got handles. Valve hoses partly renewed. Hydraulic pump sound insulated. New LED tube light.

Overview

- brand: DECKEL MAHO

- year: 1999

- MODEL: DMU 80P

- production hours: 27389

- application type: Milling

- Location: Germany

- machine type: Universal Machining Centre

- control unit brand: HEIDENHAIN

Technical Information - DECKEL MAHO DMU 80P

Control Unit

- Model: TNC430

- Brand: HEIDENHAIN

Main drive

- Spindle speed range: 8000 1/MIN

Movement

- X-AXIS Movement: 800 mm

- Y-AXIS Movement: 700 mm

- Z-AXIS Movement: 600 mm

- A-AXIS Movement: 45°

- B-AXIS Movement: Horizontal/Vertical

- C-AXIS Movement: 360°

Tools

- Max weight: 630 kg

- Type of tool holder: SK50

Media

- Chip conveyor: Yes

- Internal cooling: Yes

Additional Information

Additional equipment

- 50 tool holders

- Tools

Machine Benefits

Qualitative Machine Benefits

- Air pressure controller with filter

- New led tube light

- Hydraulic pump sound insulated

- Valve hoses partly renewed

- New switch on button green. The control panel has got handles

- Inside and outside incl. Spindle cover new painted and new inscriptions received

- Aluminium cover strips has been renewed on the side

- Many tool holders converted to ik

Technical Machine Benefits

- Electronic handwheel

- 5 water jets and 5 air jets

- Spindle with internal cooling and tool magazine 30x

- Tlc software version: gr472. 01r

- Nc software version: 280476-29

- Coolant tank 600 litres

- Coolant pressure 20-40 bars

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to DECKEL MAHO DMU 80P

GX 600

Bridgeport - Vertical Machining Centre

TC 32B

Brother - Vertical Machining Centre

HS500i

HYUNDAI KIA - Horizontal Machining Centre

F5

Makino - Vertical Machining Centre

MTV 655/60N

Mazak - Vertical Machining Centre

DECKEL MAHO DMC 60H Linear

DMG - Horizontal Machining Centre

NHP 5000

DN SOLUTIONS - Horizontal Machining Centre

UMC-500SS

HAAS - Universal Machining Centre

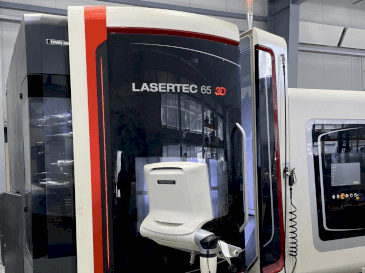

LASERTEC 65 3D Hybrid

DMG MORI - Universal Machining Centre

TM 2

HAAS - Vertical Machining Centre

Robodrill D21MiA5

FANUC - Vertical Machining Centre

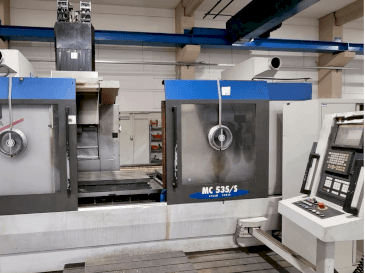

MC 535

STAMA - Vertical Machining Centre